KP -CASE ERECTING AND FILLING MACHINE

P&S - Your experts for fully automatic case erecting and filling machines!

In a world where efficiency and precision are crucial, we offer innovative solutions to take your packaging processes to the next level.

Our fully automatic case erecting and filling machines are designed to optimize your production processes while meeting the highest standards of quality and reliability. With state-of-the-art technology and innovative functions, we enable seamless integration into your existing production line.

Whether you are active in the food, pharmaceutical or consumer goods industry, our machines offer a wide range of applications. Thanks to precise carton placement and efficient filling, we not only ensure increased production capacity, but also a reduction in waste and operating costs.

Our focus is on customer satisfaction and customized solutions. Our experts work closely with you to understand your individual requirements and offer you the perfect solution. Put your trust in our many years of experience and let us pave the way to more efficient and cost-effective packaging production together.

Discover the future of packaging technology - discover the performance of our fully automatic carton erecting and filling machines. We will be happy to provide you with further information and personal advice.

Increase your efficiency. Fast and precise case erection and efficient filling lead to an overall increase in production speed.

The case erecting and filling machines from P&S are characterized by their precise case erection and filling. The high quality of the packaging solutions minimizes waste and ensures consistent product quality.

APPLICATIONS

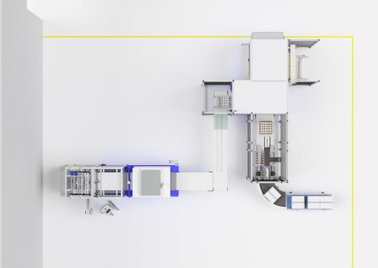

The P&S case packer is versatile and can be used as a stand-alone unit or as part of our small roll production solution. This case packer can handle a variety of products, be it single rolls of receipts or roll packs in shrink wrap or other goods. Connection to the end of an RPL separator or FB550 sleeve wrapper allows seamless integration into various production processes.

A horizontal magazine stores carton blanks and automatically feeds them to the carton erector and the closing unit. The open, erected cartons are ready in the loading area, while products are collected and packed layer by layer using a robust grouping and vacuum gripper system. A wide variety of layer packing schemes can be flexibly adapted using the standardized quick-change gripper mechanism.

As soon as the correct number of layers has been inserted, the carton is transferred to the lid closing system and securely closed with adhesive tape. Optionally, a printing and labeling system can be used to mark each carton on the outfeed conveyor before it leaves the machine.